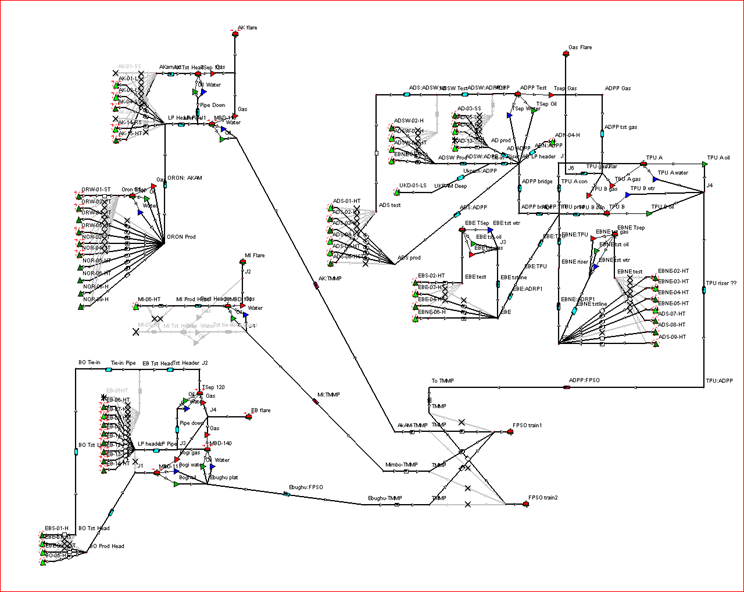

Facility Debottlenecking and Production Optimization Study

This detailed study included the development and history matching of an PROSPER-GAP model for a client to assist with gas lift optimisation. This project also included the development of a bespoke OpenServer controller to automate updating the model with new well tests and running optimisation scenarios.

Integrated Production Model

Benefits

The model identified all the bottlenecks in the system and quantified the expected production improvement once they were resolved. The asset benefited from improved production monitoring and surveillance based on well model validation to tests. With frequent well validation, production problems were easily detected and are now reviewed proactively as opposed to reactive measures. Opportunity to optimize production based on improved gas lift gas allocation to the wells was also identified. The IAM suite of tools features a non-linear network solver algorithm that helps optimise gas lift gas to maximize production within a production system.