PVT Modelling and Fluid Characterization Fundamentals Part 1

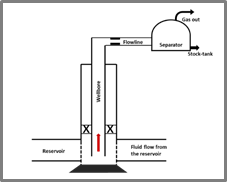

PVT modelling involves the mathematical description of the behavior of hydrocarbon fluids as a function of pressure and temperature. As hydrocarbon fluids flow from the reservoir through completions and flowlines to the surface, they tend to exhibit different behavior at these different points. This is because of the changes in pressure and temperature conditions. Continuous production from the reservoir also results to reduction in reservoir pressure which in turn affects the behavior of the fluids.

The aim of any PVT model therefore is to correctly replicate the evolution of the fluid properties/behavior with changing conditions either downhole or at the surface.

Methods of PVT Modelling

There are two general methods of PVT modeling commonly applied in the oil and gas industry: Black Oil (BO) and Compositional Equation of State (EoS) PVT Modeling.

Black Oil (BO) PVT modelling is a 2-component description of the hydrocarbon fluids as” surface gas” and “stock tank oil”. This PVT modelling method is widely used due to its simplicity and because it requires limited inputs. This method relies on empirical correlations derived from oil samples taken from different regions and at varying conditions. As a result, each BO correlation is best suited for a specific type of oil and within some bounding conditions.

Equation of State (EoS) PVT modelling is a multi-component description of the hydrocarbon fluids based on the alkane series. This method is much more detailed and requires more data than the BO modelling approach. Building an EoS PVT model will require at a minimum the composition of the reservoir fluids and properties of the pseudo components. In addition, other laboratory experiment data will be required to further tune/calibrate the EoS model.

Application of PVT Modelling

At the reservoir, PVT properties like formation volume factor (Bo) are required for reserve estimation, volume changes, and other material balance calculations. Numerical simulators also require PVT tables to correctly simulate saturation and pressure changes in the reservoir.

Within the wellbore, flowlines and surface processing facilities, PVT properties are used for pressure drop and thermal calculations.

A good handle on the PVT is required for flow assurance calculations, process design, surface equipment performance optimization etc. The accuracy of the PVT model has a huge impact on all other calculations in the production system hence the need to pay attention to the PVT modelling process.

Before going ahead to build a PVT model, a decision will first have to be made on which modelling approach is suitable; BO or EoS. Often, this decision is not quite straight forward. While it may not be correct to say one method is better than the other, each method has specific situations when and where they are most preferred. Generally, the choice of the PVT modelling approach will depend on factors like; available data, nature of the fluids to be modelled, the modeling objectives etc. A proper understanding of the BO and EoS modelling methods will also go a long way in helping the engineer make this critical decision. Even after deciding on a modeling method, other critical decisions will still be made downstream like; what BO correlation or EoS method to use, if to take the input data from flash or differential liberation experiment, what to do when there is limited laboratory data etc. Subsequent publications in this series will discuss each of the modelling methods in-depth.

In our IPM Course, we go deeper into the fundamentals and mechanics of the BO PVT modelling technique, we discuss the expected behavior of key PVT properties with changing conditions, the best practices in choosing BO correlations with and without match data. The EoS modelling technique is extensively covered in the Advanced IPM Course with case studies involving step by step EoS modelling exercises. You can contact us via email or phone call to get more details.

Attend one of our courses to learn more: IPM Course and Advanced IPM Course or contact info@accreteltd.com; trainings@accreteltd.com

© 2021 ACCRETE PETROLEUM LIMITED